EXA Embedded Technology

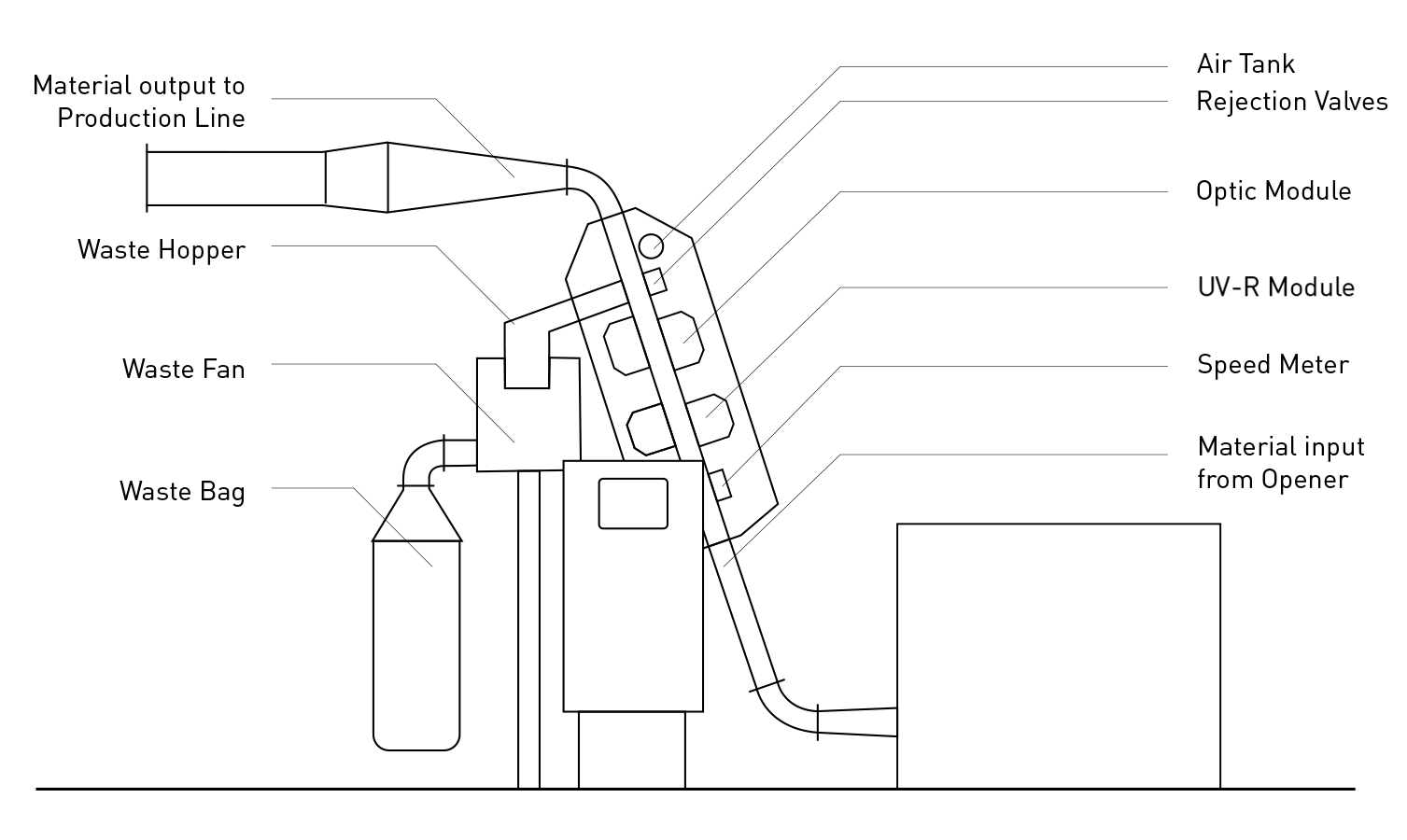

EXA Embedded Technology consists of arrays of in-house color cameras coupled with source of lights at different spectrum. It allows a comprehensive identification of contamination, foreign fibers and material defects in textiles.

These technologies face the critical and harsh conditions of preparation and processing lines. Low maintenance costs, easy friendly software and full automation complete the design.

Identification of contamination

Loptex follows basic and straightforward criteria for contamination and material defects identification. EXA Embedded Technologies identifies those contaminants and defects which have a negative impact on downstream processes, fabrics and finished webs. State-of-the-art solutions provide the tools for these identifications.

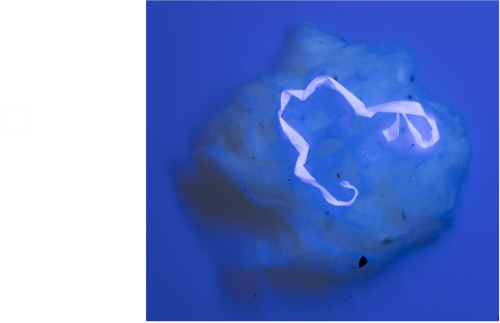

UV light spectrum

Identification of optically brightened contamination.

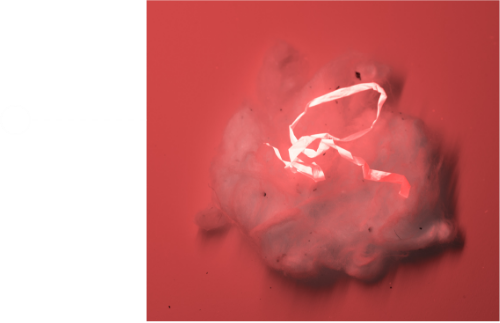

Red light spectrum

Identification of glossy contamination surface.

White light spectra

Identification color and light color contamination.

Removal of contamination

Loptex EXA separates contamination in a continuous fibers flow. It does not interfere with the production of the line. It guarantees efficient removal of contaminants.

Array of solenoid valves

The array of solenoid valves enables on-time separation of contamination. Only one valve is activated for the targeted expulsion of the contaminant.

Intelligent software

Intelligent software synchronizes the detection systems with the solenoid valves through dedicated hardware. Each valve contains three nozzles.

Minimum loss of non-faulty material

The filtering of cotton tuft shadows and the measuring of their speed allow significant reduction of false rejections. The loss of good fibers is then reduced to its minimum.

Classification

Loptex EXA captures the contamination images and classifies them according to color and size.

More

More

Spinning

Easy Link EXA

The Easy Link EXA upwards fibers flow is a space-saving solution to existing and new compact blow room lines. It is recommended to process high contaminated cottons. It monitors a production up to 1000 Kg/h. On demand, it monitors a production up to 1200 Kg/h.

More

Nonwovens

Easy Link EXA - NW

The Easy Link EXA-NW upwards fibers flow is a space-saving solution to existing and to new compact nonwovens blow room lines. It monitors a production up to 1000 Kg/h. On demand, it monitors productions up to 1200/2000 Kg/h.

More

Flakes and Fibers Recycling

Easy Link EXA

The Easy Link EXA upwards fibers flow is a space-saving solution to existing and new tearing lines. It is recommended to process post-industrial and post-consumer flakes and recycled fibers. It monitors a production up to 1000 Kg/h. On demand, it monitors a production up to 1200/2000 Kg/h.

More

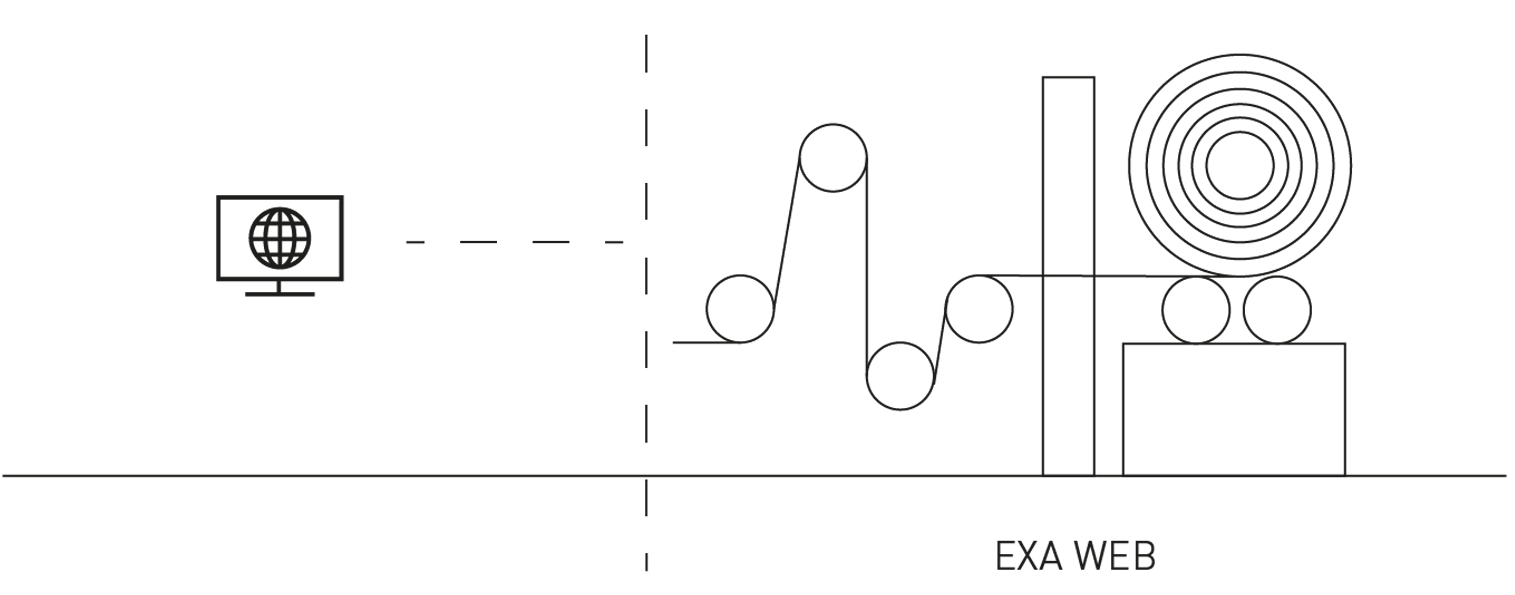

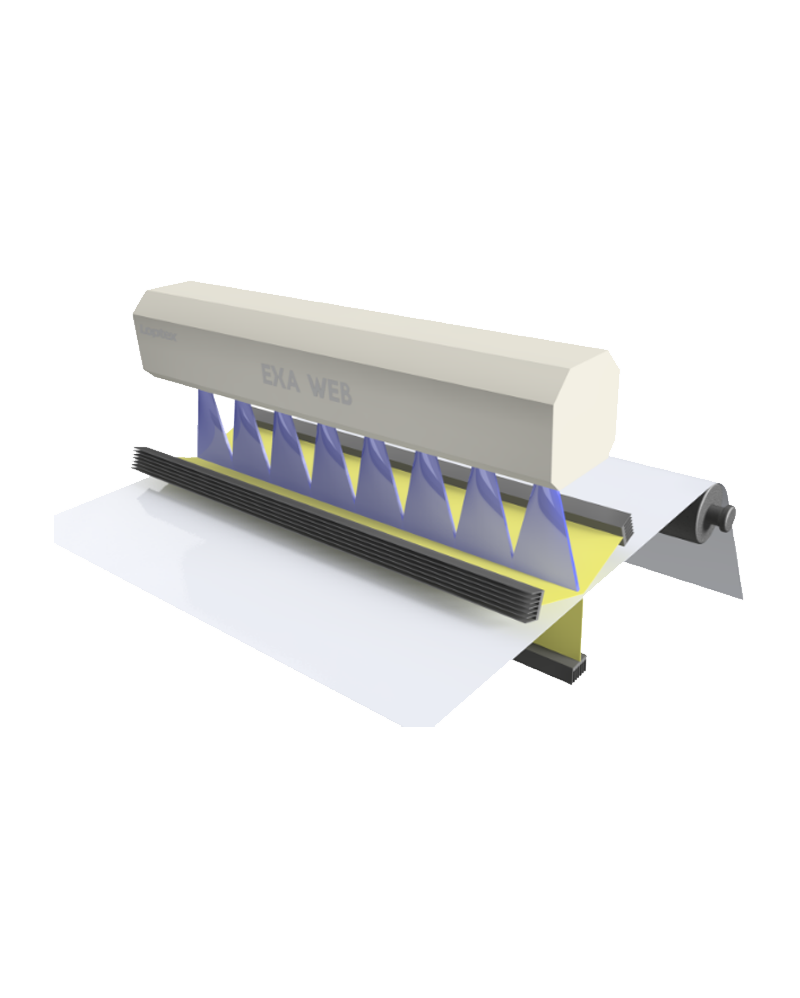

Nonwoven & Technical Textiles. EXA Webs

EXA Web identifies the remaining of contamination and defects on finished webs and provides their mapping distribution on the rolls. It is a complementary solution to the Easy Link EXA NW system installed at the beginning of the process before cards. This combined solution offers a total control of contamination and defects in Nonwovens and Technical Textiles.

MoreEXA Versatility and Compliance

EXA modular concept leads to tailor – made solutions on customer demand. EXA combines multiple technologies which identify and analyze contamination of natural, artificial, synthetic fibers and material defects. EXA monitors different fiber mixing and colors. EXA identification performance, through arrays of embedded color cameras coupled with a combination of source of lights, features:

-Direct viewing with high resolution and accuracy.

-Elimination of optical side distortion.

-Completely sealed optical path.

-Constant sensitivity level on whole inspection field.