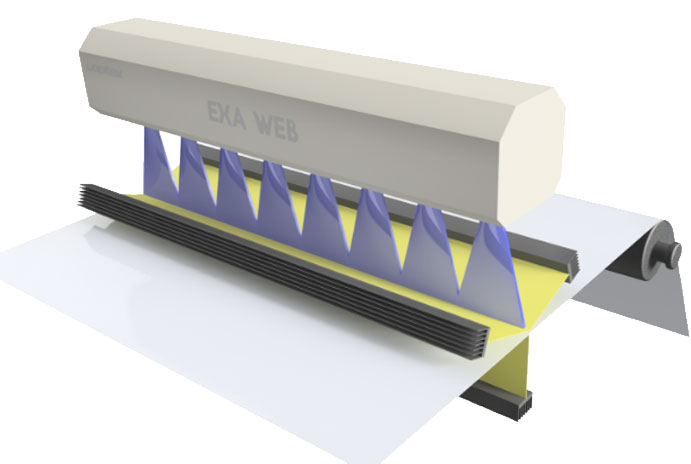

EXA Web

EXA Web through automatic calibration and fine tuning, identifies and classifies color and light color contamination, dirt, thin areas, holes, industrial debris and other. The in-house color cameras at high resolution and accuracy meets the demand of comprehensive identification of all disturbing contamination and material defects.

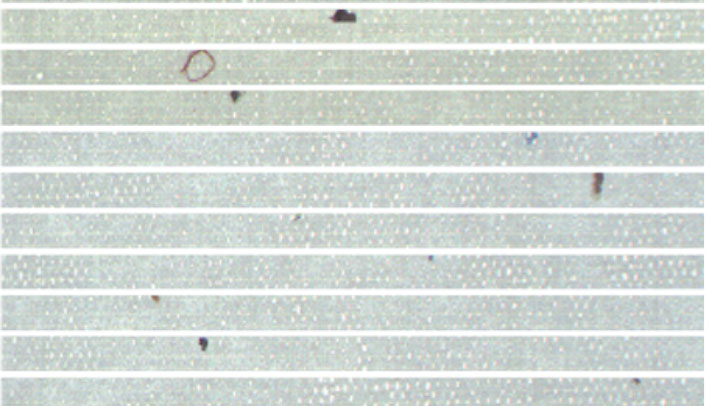

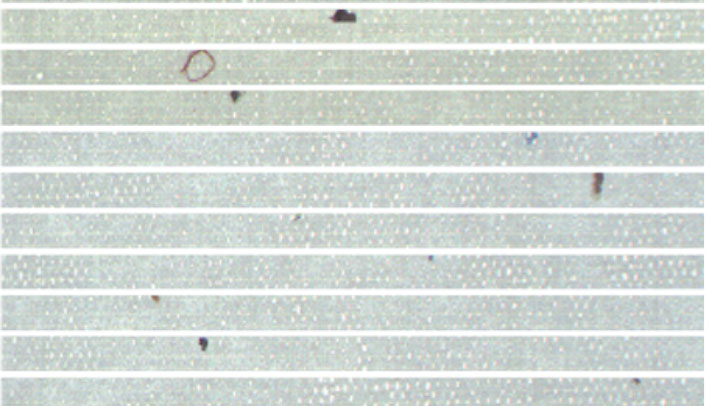

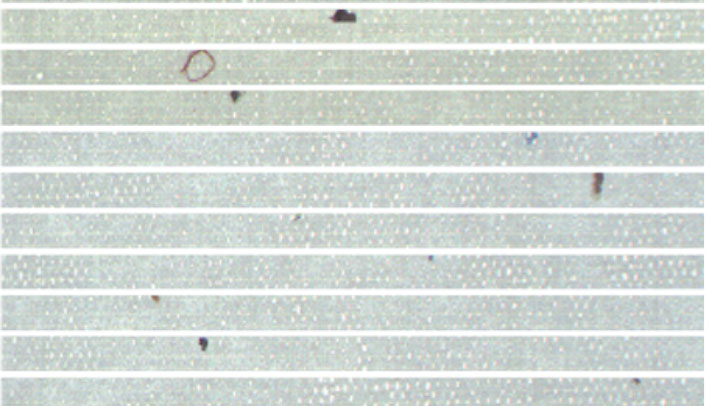

Example of sorting waste:

EXA WEB

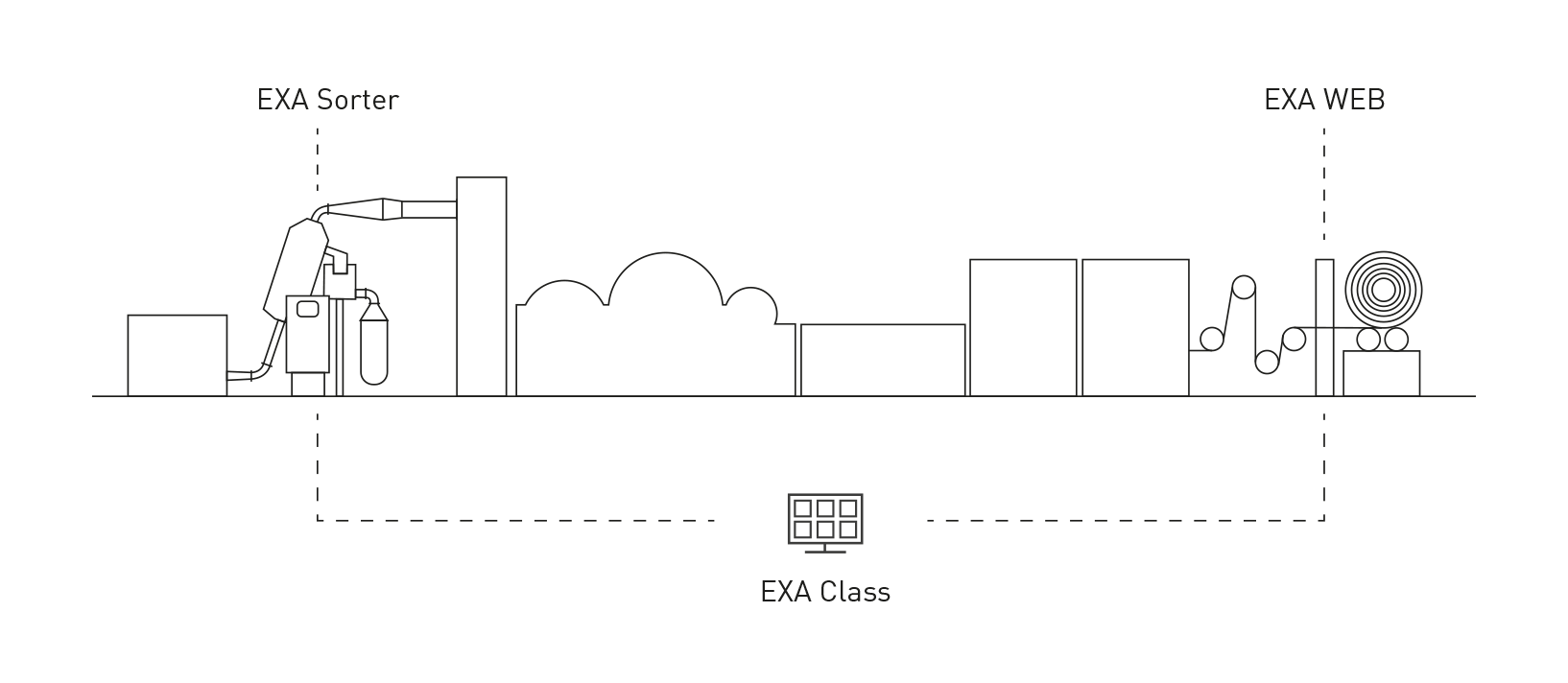

Remote control

VPN connection to Loptex head quarter. It enables the optimization of settings and calibration and provides to operators full assistance. Through virtual sensors features predictive maintenance analysis and on-line control of components.

Features

Modular concept

Sealed cameras and lenses optical path

Self-calibration and automation

Easy maintenance

Fast ROI

Option

Remote control

Link to EXA Class (Historical Data and Classification of Contamination).

Maximum control and reduction of contamination. Yield improvement.

EXA Web coupled with Easy Link EXA NW installed before carding process, identifies and classifies the remaining of the contamination on finished webs. This combination contributes to reduce the content of contamination of raw material and to optimize the control on finished web. It also contributes to identify the origin and cause of contamination at all stages of the production process. It leads to significant quality improvement of finished webs and best production yield.

EXA Class

EXA Class is a Data Acquisition and Contamination Classification System. It downloads statistical data and contamination images from the Sorter units. It classifies the contamination according to color and size. Furthermore, it provides important quality information on processing material.

More