Spinning - The most comprehensive and accurate system for the detection and removal of contamination

Loptex is the first company in the market that introduced the concept of sorting out contaminants from a free fibers stream through pneumatic valves with minimum loss of lint. The application refers to preparation lines at the beginning of the process before carding machines. This concept led to the design of a unique system to be integrated in existing and in new blow room lines of any brand. Loptex, through in-house embedded technologies, faces the critical environment conditions of the opening process. The modular design, the high resolution and accuracy of the color camera system and the use of multiple light sources, enhance the comprehensive detection and the elimination of all type of contamination. The unique Loptex know-how optimizes the combination of multiple embedded technologies. Harmful contamination visible on fabrics follows spinnability and non-dyeability criteria. Loptex, as leading company on contamination control in cotton Spinning Mills, is present in all the major textile areas in the world assuring sale and after sales support to its customers.

Contamination may be:

Light thin colour PP strings.

Spinnable and non-dyeable

White PP.

Spinnable and non-dyeable

Colour PP strings.

Spinnable and non-dyeable

Dead and immature fibres.

Spinnable. Neps generation. Non-dyeable.

Feathers.

Spinnable and non dyeable

Threads.

Spinnable and dyeable.

Colour pieces of fabrics.

Spinnable and dyeable

Jute.

Spinnable and dyeable

Plastic films.

Non-spinnable.

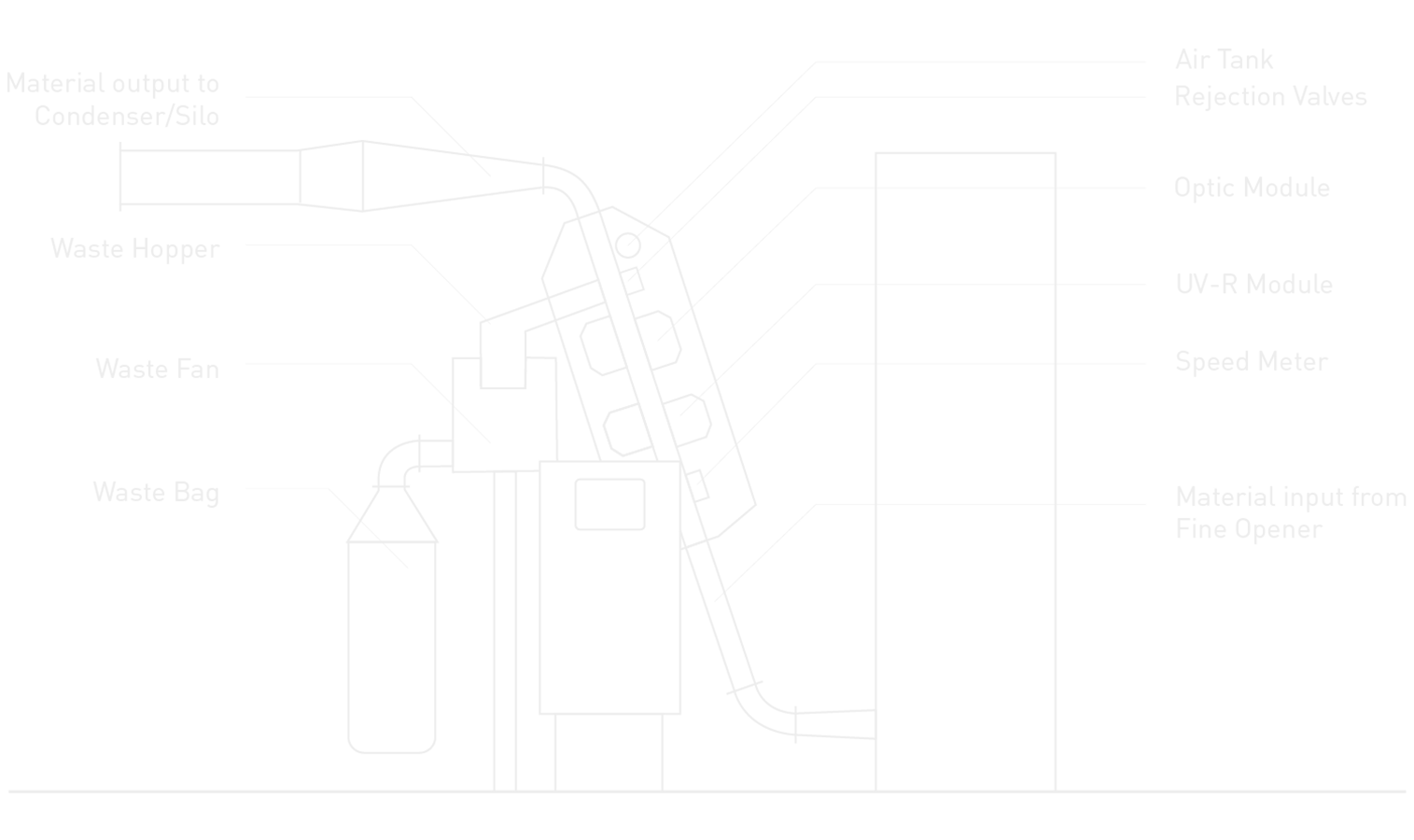

EASY LINK EXA

The Easy Link EXA offers a space-saving saving solution to existing and new blow room lines.

Features

Upward fibres flow

Perfect fitting on existing fibre stream

Modular concept

Minimal loss of non-faulty material

Automation

Option

Remote control

Link to EXA Data

Techical specification

Max production:

1000 Kg/h (1200 Kg/h on demand)

Power supply:

400 VAC ± 10% 50Hz.

Installed power:

1 kW (EXA system)

1 kW (Waste extraction system)

Air consumption:

0,6/1,2 NL (per contamination removal)

Compressed air supply:

approx. 6-8 bars

Dimensions:

Height 3270 mm

Width 2070 mm

Depth 750 mm

Loptex reserves the right to change dimensions and technical specifications. Copyright reserved.

EXA Data

EXA Data, through an external PC, collects and files statistical and historical data from Sorter units.

It provides key information on machines status and on processing materials.